Manual cleaning of trays, crates and utensils has in many instances become unrealistic and uneconomic due to the high volume of items required by businesses with, for example, a large bakery requiring 2,500 baskets an hour to keep production flow on track.

All washing machines can be classified as either conveyor type or single tank machines.

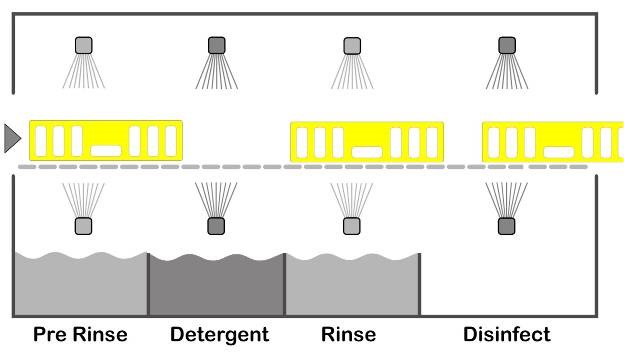

The schematic shows a 3 tank conveyor tray wash with disinfection section. Configurations of tray wash machines will vary dependant on the specified requirements.

Items are placed on a conveyor which transports them through the various stages of the washing process, with each stage occurring in a different section of the washer; pre-rinse, wash with detergent, rinse, disinfect chemically or by temperature and then dry.

Smaller washers are based on the same principle but leave out certain sections. Typically, smaller washers are configured with a detergent section and a hot water final rinse section (sometimes in excess of 82°C to achieve thermal disinfection).

Two or more operators are typically needed for this type of tray wash machine.

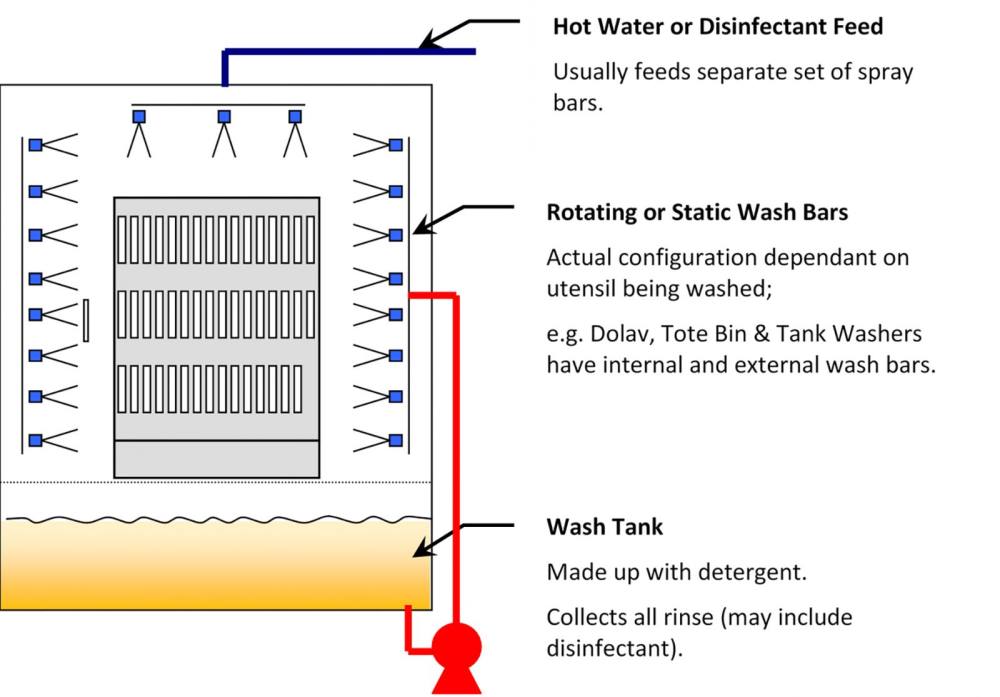

The configuration shown is typical of a rack washer. Configuration of washers will vary. Note: These types of machines are usually fitted with a rotating jet in the centre to clean interior surfaces.

One operator is usually needed for this type of automated washing machine.

In both types of washing machines certain cleaning solutions are reused (e.g.detergent). These solutions are a vector for allergens transfer. This is one of the reasons why it is important to have a clean water or disinfectant feed for the final rinse and it should be sufficient in volume to rinse away any debris and detergent on the item being washed. It is important that the whole washing process is validated for both microbial cleanliness (if appropriate) and freedom from allergen.